Liquid-Assisted Gas-Lift Technology

This technology can remove ALL the downhole equipment from your well...

The Liquid-Assisted Gas-Lift (LAGL) concept

The Liquid-Assisted Gas-Lift is a solution for artificial lift for unconventional wells, as well as conventional vertical wells. The method, termed Liquid-Assisted Gas-Lift (LAGL), is an enabling technology for lifting liquids, solids, and gas out of your well. These key issues currently limit wider use of ESPs and conventional gas-lift.

The LAGL concept utilizes the co-injection of liquid with gas to eliminate the use of downhole valves and reduce surface pressure requirements for the kick-off of gas-lift.

The LAGL technology utilizes no valves at all, which simplifies the well completion versus the traditional use of multiple gas-lift valves and mandrels; this dramatically reduces the risk of tubing-to-casing leak and the frequency of well interventions while improving overall well integrity and safety.

Our experts perfected proprietary algorithms and techniques through multiple lab testings. We have proven we can lower the surface injection pressure requirements up to 75%. Our hope is to reduce carbon emissions and improve the field environment safety conditions at the well-site.

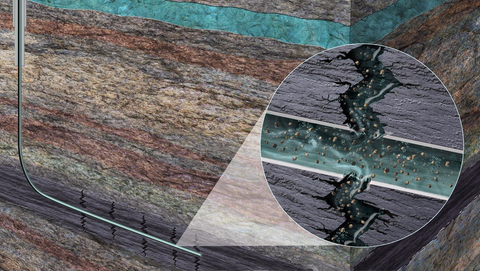

In regard to managing flow patterns, slugging is the most troublesome flow pattern, and large slugs can fill up the horizontal section and kill wells. The Lift POD had unconventional wells in mind: our unit can change the gas-liquid flowing velocities in the entire wellbore, including the horizontal portion of the well, which can eliminate slugging in horizontal wells!

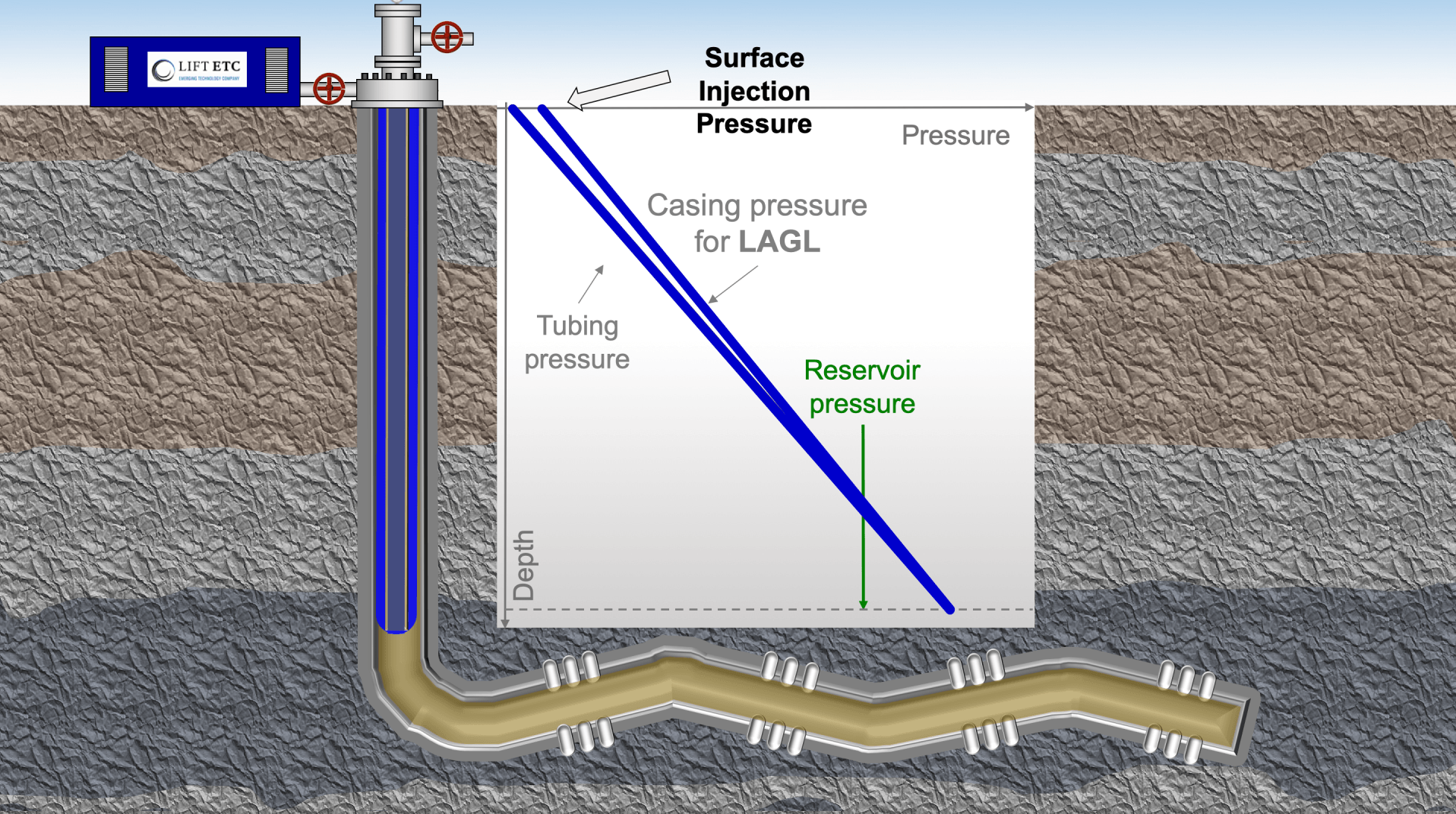

Low injection pressure

This Liquid-Assisted Gas-Lift is an alternative technique to perform the gas-lift unloading process. In the LAGL, the injection fluid is a mixture of gas and liquid. The main objective of having the injection of a gas-liquid mixture is to increase the mixture density of the fluid in the casing annulus, which consequently decreases the necessary injection pressure for gas to reach the bottom of the well.

Guaranteed single-point injection

The Liquid-Assisted Gas-Lift (LAGL) process is similar to the conventional unloading process. However, conventional gas-lift unloading often suffers from multipoint injection, which decreases production often more than 30%. The use of the LAGL technology can eliminate multipoint injection for the unloading process, thus, it can improve production when compared to conventional gas-lift, and can also improve production compared to other artificial lift methods such as ESPs.

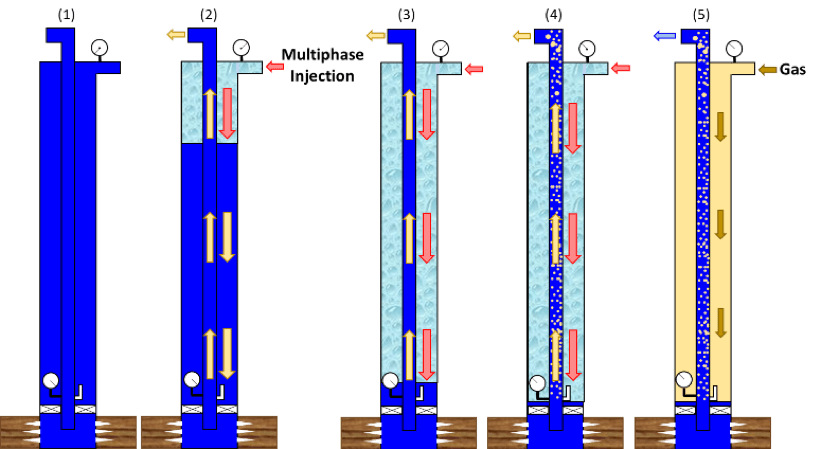

The LAGL unloading process can be divided in four steps:

1 - Both annulus and tubing are partially filled with liquid (formation and/or completion fluids). The injection pressure is low, and the bottomhole pressure is high due to the large hydrostatic pressure of the liquid.

2 - Multiphase fluid (gas-liquid mixture) is injected in the annulus pushing part of the liquid out the tubing. Bottomhole pressure would be the same as step 2. However, the injection pressure is lower due to the higher fluid mixture density in the annulus, as a consequence of the injection of gas and liquid.

3 - Gas reaches the GLV and starts to flow upward in the tubing. The presence of gas in the tubing lowers the mixture density of the fluid in the tubing, which consequently decreases the bottomhole pressure.

4 - The Gas-Liquid-Ratio (GLR) of the injected gas-liquid mixture is slowly increased to a point when only gas is injected. At this moment the LAGL unloading process ends and the conventional gas lift process is initiated.

Efficient delivery of chemicals

The Lift POD also enables the application of chemicals from the TOE such as corrosion and scale inhibitors. And of course, all this can be achieved without human intervention or monitoring, as the Lift POD system has been designed and validated to operate autonomously.

Remote updates to optimize production without well intervention and production downtime

The Lift POD can be updated "over-the-air" using remote-internet access. These updates allow for the Lift POD to effectively optimize production over the life of unconventional wells, as unconventional reservoirs rapidly change pressure, gas-liquid-ratio, and productivity index. Regardless of how many Lift POD units are deployed, the updates are all possible without well intervention or loss of production.